Crafting Excellence in Harness Manufacturing

Precision in Every Connection

ISO 9001:2015

A Pillar of Quality Management

IPC WHMA-A-620B

Redefining Industry Standards

The Art of Crafting Harness Assemblies

From Concept to Creation

Advantages of Choosing THD Africa

Our Turnkey Process Overview

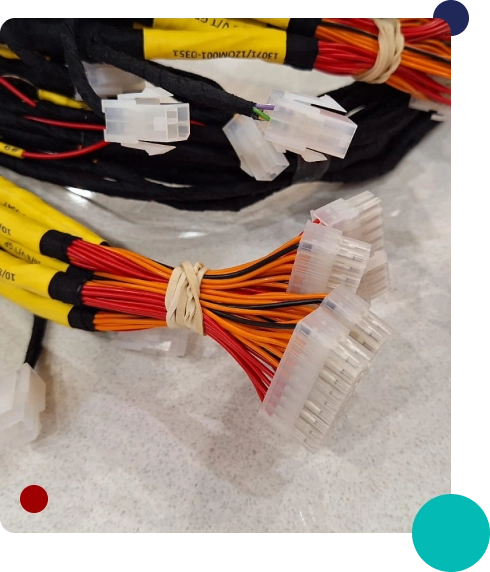

Our manufacturing capabilities and expertise shine as we bring designs to life. With cutting-edge machines and equipment, we uphold the highest standards in every step of the production process.

Precision Unleashed

Our Manufacturing Approach

1. Production Works order route sheets

Data pack and configuration control. Full traceability of work conducted: Operators, Machines.

2. Cutting

In the cutting phase, precision is paramount as we employ cutting-edge technology for accurate incisions. This process aligns with rigorous industry standards, showcasing the skill and expertise that lay the foundation for excellence.

3. Stripping

Stripping, a crucial step demanding precision, is executed with the utmost attention to detail, aligning with industry benchmarks.

4. Crimping

Crimping, a pivotal step in harness manufacturing, is executed with precision.

5. Pull Force Testing

The Pull Force Testing phase is a testament to enduring quality.

6. Heat Shrink/Labelling and identification

In harness assembly, Heat Shrink, Labelling, and Identification ensure precision.

7. Harness Assembly & Integration

This symphony of precision and expertise aligns with industry standards.

8. Solder and Tin Dip

Solder and Tin Dip, transformative processes that elevate connectivity, adhere to industry standards.

9. RF Striping

In the specialized process of RF Striping, precision in signal integrity is paramount.

10. RF Testing

The RF Testing phase ensures optimal performance, aligning with industry standards. Join us in exploring how this phase ensures our harness assemblies deliver unmatched performance.

Elevating Wire Harnessing Standards

Our Commitment to Wire Harnessing Excellence

Reach Out to Us

Let's Get Started

- +27 10 510 9390

- customerservice@thdafrica.co.za

-

Unit 99, Allandale Exchange

917 Morkels Close

Halfway House

Midrand,

Johannesburg

South Africa

1685