Elevating Quality Standards

ISO 9001:2015 and IPC WHMA-A-620B - Setting the Bar for Excellence

At THD Africa, quality is not just a standard; it’s a commitment. We adhere to the globally recognised ISO 9001:2015 Quality Management System, ensuring our processes are fine-tuned for perfection.

Our cable and wire harness assemblies meet the rigorous requirements of IPC WHMA-A-620B, defining industry benchmarks for workmanship, testing, safety, and documentation.

Validation Beyond Limits

Precision in Every Test

Each test in our repertoire serves as a testament to our dedication, ensuring that every product surpasses expectations and stands ready for the most demanding applications.

Advanced In-House Testing

Your Assurance of Quality and Reliability

Ensuring Electrical Integrity

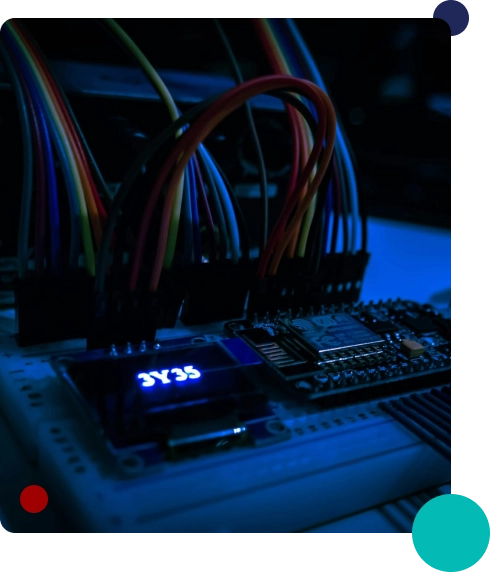

Cirris Testing

We employ state-of-the-art cable and harness testers from Cirris Systems Corporation to ensure the electrical integrity of our assemblies. These advanced testing machines are designed to assess various parameters, including continuity, resistance, dielectric breakdown, insulation resistance, and fault identification. The versatility of Cirris testers allows us to thoroughly evaluate each assembly, leaving no room for undetected issues.

Ensuring Robust Harness Assemblies

Cami Testing

Unleashing Optimal Performance

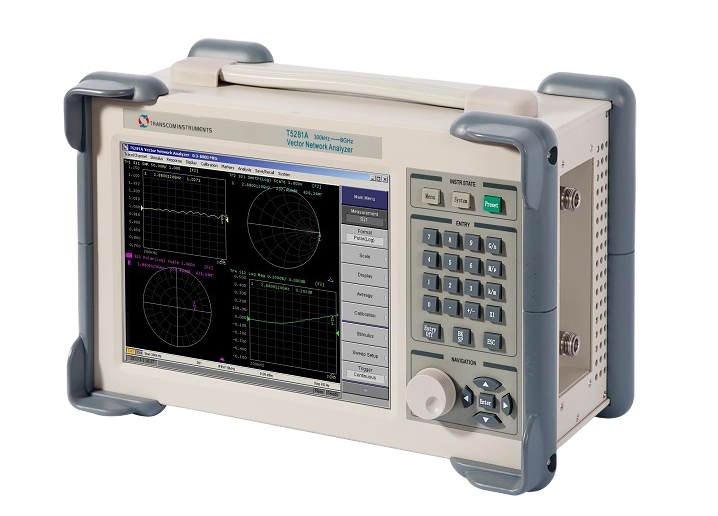

RF Testing

In the realm of Radio Frequency (RF) applications, THD Africa employs cutting-edge tools to validate optimal performance. The Transcom T5231A and Transcom Vector Network Analyser are integral components of our RF Testing process, setting new benchmarks for reliability in our harness assemblies.

Validating Enduring Connections

Pull Force Testing

Advantages of Choosing THD Africa

Confidence, Resolution, Excellence

Customer Confidence

Our adherence to global quality standards instills confidence, assuring you of robust and reliable solutions.

Complaint Resolution

We navigate challenges efficiently, offering guidelines for prompt and satisfactory complaint resolution.

Process Improvement

Identify and eliminate inefficiencies with our commitment to continual improvement, ensuring streamlined operations.

Ongoing Optimisation

Regular audits and reviews enable us to refine our processes, stay competitive, and achieve long-term success.

Elevating Manufacturing Standards

Our Commitment to Manufacturing Excellence

Reach Out to Us

Let's Get Started

- +27 10 510 9390

- customerservice@thdafrica.co.za

-

Unit 99, Allandale Exchange

917 Morkels Close

Halfway House

Midrand,

Johannesburg

South Africa

1685