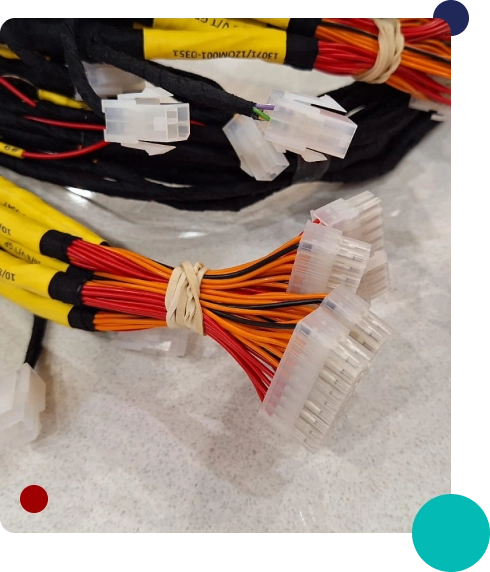

Precision in Wire Harness Manufacturing

Meticulously Crafting Wire Harness Assemblies

Elevate your expectations with THD Africa’s commitment to precision and excellence in wire harnessing. We embark on a journey of uncompromising quality, meticulously crafting wire harness assemblies that exceed industry standards. Adhering to ISO 9001:2015 as our operational benchmark and IPC/WHMA-A-620 as our manufacturing standard, we redefine wire harnessing standards for a multitude of industries.

Elevating Manufacturing Standards

Our Commitment to Manufacturing Excellence

Certifications: Upholding the highest international quality standards, our factory operates in accordance with ISO9001:2015 as our operational benchmark and adheres to IPC/WHMA-A-620 as our manufacturing standard.

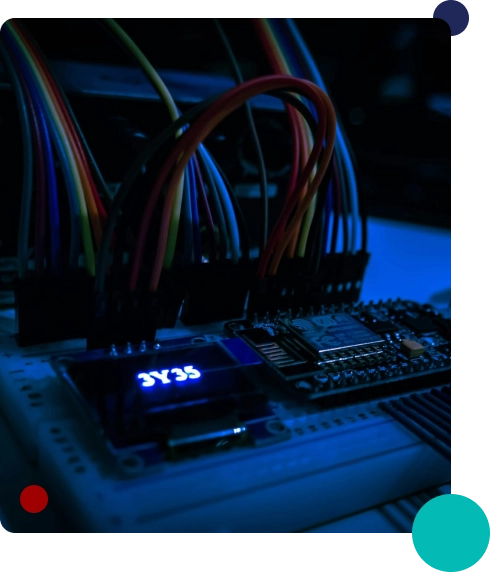

Advanced In-House Testing

Your Assurance of Quality and Reliability

Various Comprehensive testing processes and capability available inhouse includes: Crimp Pull force Test, Instantly measure, display, and document basic electrical properties such as continuity, resistance, dielectric breakdown, insulation resistance, miss-wires, twist pair relationships, and intermittent faults. We perform wiring analysis, diagnostics, Pass/Fail checks, and test automation. RF Vector Network Analyser – frequency range: 300kHz to 3.0GH

Industries We Serve: Versatile Applications

Serving Reliable Connectivity Across Industries

Our wire harnesses find applications across diverse industries, ensuring reliable connectivity and superior performance. THD Africa’s wire harness assemblies cater to the following sectors:

- Aviation

- Aerospace

- Military

- Mining

- Industrial

- Telecoms

- Fleet Management

- BMS Wiring for Renewable Energy

- RF (Radio Frequency)

- Renewable Energy

- Solar Applications

- Cash Management Systems

Advantages of Choosing THD Africa

Our Turnkey Process Overview

From the inception of a project, we delve into the intricacies of design and development, crafting engineering drawings and samples that lay the foundation for excellence. Our planning phase encompasses meticulous sourcing, Material Requirements Planning (MRP), and strategic logistics, ensuring a seamless journey from concept to creation. This turnkey approach is the backbone of our commitment to delivering precision in every harness assembly. Join us on this journey, where attention to detail meets the innovation of turnkey manufacturing.

We define the scope of each project with a meticulous approach, ensuring that we understand the unique requirements and challenges. This initial step sets the tone for a successful and efficient manufacturing process.

Our engineering prowess comes to life in the design and development phase. Crafting detailed engineering drawings and engineering samples, we set the stage for the creation of harness assemblies that meet and exceed expectations.

Efficient planning is the cornerstone of our manufacturing process. From sourcing the finest materials to employing Material Requirements Planning (MRP) strategies, we ensure a streamlined and efficient journey from concept to creation.

Our manufacturing capabilities and expertise shine as we bring designs to life. With cutting-edge machines and equipment, we uphold the highest standards in every step of the production process.

Quality is not just a goal; it’s an ongoing commitment. Throughout the manufacturing process, we conduct random quality inspections to ensure that each component and assembly meets our rigorous standards.

Stringent testing procedures validate the excellence of our harness assemblies. Utilizing state-of-the-art testing equipment and following industry standards, we ensure the reliability and durability of our products.

Before reaching our clients, each harness assembly undergoes a thorough final inspection. This ensures that only products of the highest quality, precision, and reliability are delivered.

Certificate of Conformance: Our commitment to transparency is reflected in the availability of production test certificates and Certificates of Conformance. These documents provide detailed insights into our testing methodologies, criteria for passing tests, and relevant data or reports, showcasing the outcomes of specific testing procedures.

Quality Mastery Unveiled

Our Commitment to Excellence

Explore the pinnacle of quality with THD Africa where we use our globally recognised certified ISO 9001:2015 Quality Management System to control Process Standard. This certification The IPC WHMA-A-620B Manufacturing Standard sets the benchmark for cable and wire harness assemblies, defining our commitment to excellence in every detail.

Reach Out to Us

Let's Get Started

- +27 10 510 9390

- customerservice@thdafrica.co.za

-

Unit 99, Allandale Exchange

917 Morkels Close

Halfway House

Midrand,

Johannesburg

South Africa

1685